Maximizing Electrical Safety: The Essential Role of Cable Ducts in Modern Infrastructure

In an era where electrical safety is paramount, the integration of cable ducts into modern infrastructure is crucial for mitigating risks associated with electrical installations. According to a report from the National Fire Protection Association (NFPA), electrical failures are a leading cause of residential fires, accounting for an estimated $1.3 billion in property damage annually.

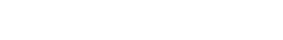

Cable ducts play an essential role by providing a secure pathway for electrical cables, protecting them from physical damage and reducing the risk of electrical malfunctions and subsequent fires. This protective infrastructure not only enhances safety but also aids in compliance with regulatory standards, such as those outlined by the International Electrotechnical Commission (IEC). As the demand for reliable and safe electrical systems continues to rise, understanding the importance of cable ducts becomes vital for engineers and safety professionals alike, ensuring that modern infrastructure remains efficient, safe, and resilient.

Cable ducts play an essential role by providing a secure pathway for electrical cables, protecting them from physical damage and reducing the risk of electrical malfunctions and subsequent fires. This protective infrastructure not only enhances safety but also aids in compliance with regulatory standards, such as those outlined by the International Electrotechnical Commission (IEC). As the demand for reliable and safe electrical systems continues to rise, understanding the importance of cable ducts becomes vital for engineers and safety professionals alike, ensuring that modern infrastructure remains efficient, safe, and resilient.

The Importance of Cable Ducts in Enhancing Electrical Safety Standards

In modern infrastructure, the importance of cable ducts cannot be overstated, particularly when it comes to enhancing electrical safety standards. As cities expand and electrical systems become more complex, cable ducts serve as crucial conduits that protect wiring from environmental hazards and physical damage. This is particularly relevant in areas where stringent fire safety regulations are being enforced, such as the new standards announced by Dubai Civil Defence. These regulations emphasize the importance of using materials that are resilient and fire-resistant, ensuring that electrical installations are not only efficient but also safe.

The growing U.S. electrical conduit market, valued at $1.72 billion in 2024 and projected to see a CAGR of 4.17%, reflects an increasing recognition of the role cable ducts play in safeguarding electrical systems. By providing robust management for power cables and communication wires, cable ducts help to minimize the risks of short circuits, electrical fires, and other hazards associated with poorly managed wiring. As the demand for reliable and safe electrical infrastructure continues to rise, the integration of advanced cable duct systems will be vital in meeting safety standards and protecting both people and property.

Key Design Features of Modern Cable Duct Systems for Optimal Protection

Modern cable duct systems play a crucial role in ensuring optimal electrical safety within contemporary infrastructure. One key design feature is the use of high-quality materials that provide durability and resistance to environmental factors. These materials, such as PVC or metal alloys, not only protect cables from physical damage but also offer resistance to heat and chemicals, reducing the risk of fires and electrical failures.

Another important aspect of cable duct design is effective ventilation. Proper airflow within the ducts helps dissipate heat generated by electrical cables, preventing overheating and subsequent hazards. Additionally, modular designs allow for easy installation and maintenance, ensuring that any potential issues can be swiftly addressed without major disruptions. The incorporation of features such as integrated cable management systems and entry seals further enhances safety by minimizing the risk of accidental disconnections and preventing dust and moisture from entering the ducts, thereby safeguarding the electrical infrastructure.

Maximizing Electrical Safety: The Essential Role of Cable Ducts in Modern Infrastructure

| Dimension | Description | Importance |

|---|---|---|

| Material Quality | Durable materials such as PVC and metal for longevity and safety. | Ensures protection against environmental factors and physical damage. |

| Cable Capacity | Size specifications to accommodate various cable types and volumes. | Prevents overheating and allows for easy upgrades or changes. |

| Ventilation Features | Designs that promote air circulation to reduce heat buildup. | Critical for maintaining optimal operational conditions. |

| Sealing Mechanisms | Effective sealing solutions to prevent dust and moisture ingress. | Preserves cable integrity and performance over time. |

| Fire Resistance | Use of materials that inhibit fire propagation and damage. | Enhances safety and compliance with building regulations. |

| Modular Design | Flexible systems that allow for easy expansion and rearrangement. | Adapts to evolving infrastructure needs. |

Best Practices for Installing Cable Ducts to Prevent Electrical Hazards

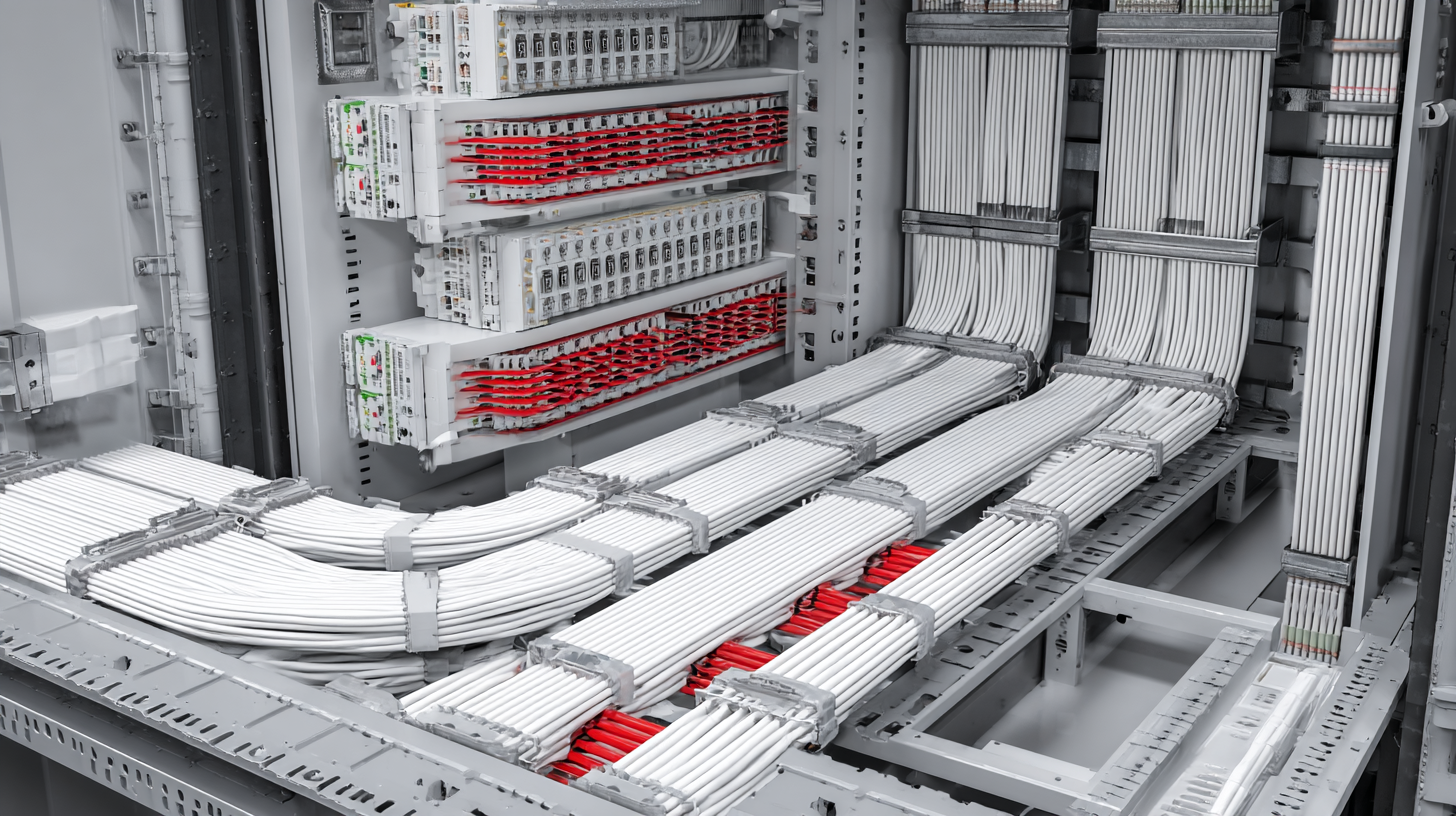

When installing cable ducts, adhering to best practices is crucial to prevent electrical hazards. Firstly, selecting the appropriate size and type of duct is essential. Each installation site has specific requirements based on the volume and type of cables being housed. This ensures optimal airflow and minimizes the risk of overheating or short-circuiting. Additionally, using high-quality materials that comply with safety standards can significantly enhance the reliability and longevity of the installation.

Proper installation techniques play a vital role in maintaining safety. For instance, ensuring that ducts are anchored securely to prevent movement reduces the risk of damage during any maintenance activities. It’s also important to maintain adequate spacing between cables within the ducts to avoid electromagnetic interference and overheating. Regular inspections should be scheduled to check for wear and tear, ensuring that the cable ducts continue to meet safety standards over time. By prioritizing these best practices, facilities can significantly mitigate electrical hazards associated with cable installations.

Regular Maintenance Tips for Ensuring Cable Duct Integrity and Safety

Regular maintenance of cable ducts is crucial for maintaining

electrical safety and integrity in modern infrastructure.

Over time, exposure to environmental factors and mechanical stress can lead to wear and tear

on cable duct systems. To prevent potential hazards, inspection should be conducted routinely

to identify any signs of damage, such as cracks or corrosion.

Keeping the ducts clean and free of debris enhances airflow and reduces the risk of overheating,

which can compromise electrical systems.

Another essential aspect of maintenance involves checking seals and joints for water or moisture ingress,

which can lead to electrical failures or short circuits. Implementing a preventive maintenance schedule

can help ensure that all components function optimally. This includes testing insulation resistance

and implementing timely repairs when issues are detected. By prioritizing these maintenance practices,

organizations can significantly enhance the lifespan of cable ducts, ensuring the safety and reliability

of electrical installations.

Innovations in Cable Duct Technology to Support Sustainable Infrastructure

Innovations in cable duct technology are playing an essential role in the development of sustainable infrastructure. As the global PVC market continues to expand, driven by the increasing demand in various sectors such as construction, automotive, and healthcare, the focus on environmentally friendly solutions has never been more critical. The PVC market size, valued at $67.89 billion in 2023, is projected to grow at a compound annual growth rate of 4.53%, highlighting the significant potential for new advancements in materials and design methods.

To maximize electrical safety and support modern infrastructure, the integration of innovative cable ducts is vital. These ducts not only provide efficient routing and protection for electrical cables but also contribute to overall sustainability goals. By utilizing rigid and flexible PVC options, stakeholders can ensure that installations are both durable and compliant with environmental standards.

**Tip:** Always consider the lifespan and recyclability of the materials used in infrastructure projects to ensure long-term sustainability. Exploring partnerships with companies focused on innovative technologies can enhance project outcomes. Investing in training for installation teams about the latest cable duct advancements can also improve safety and efficiency.