10 Essential Tips for Installing Electric Cable Ducts Safely and Effectively

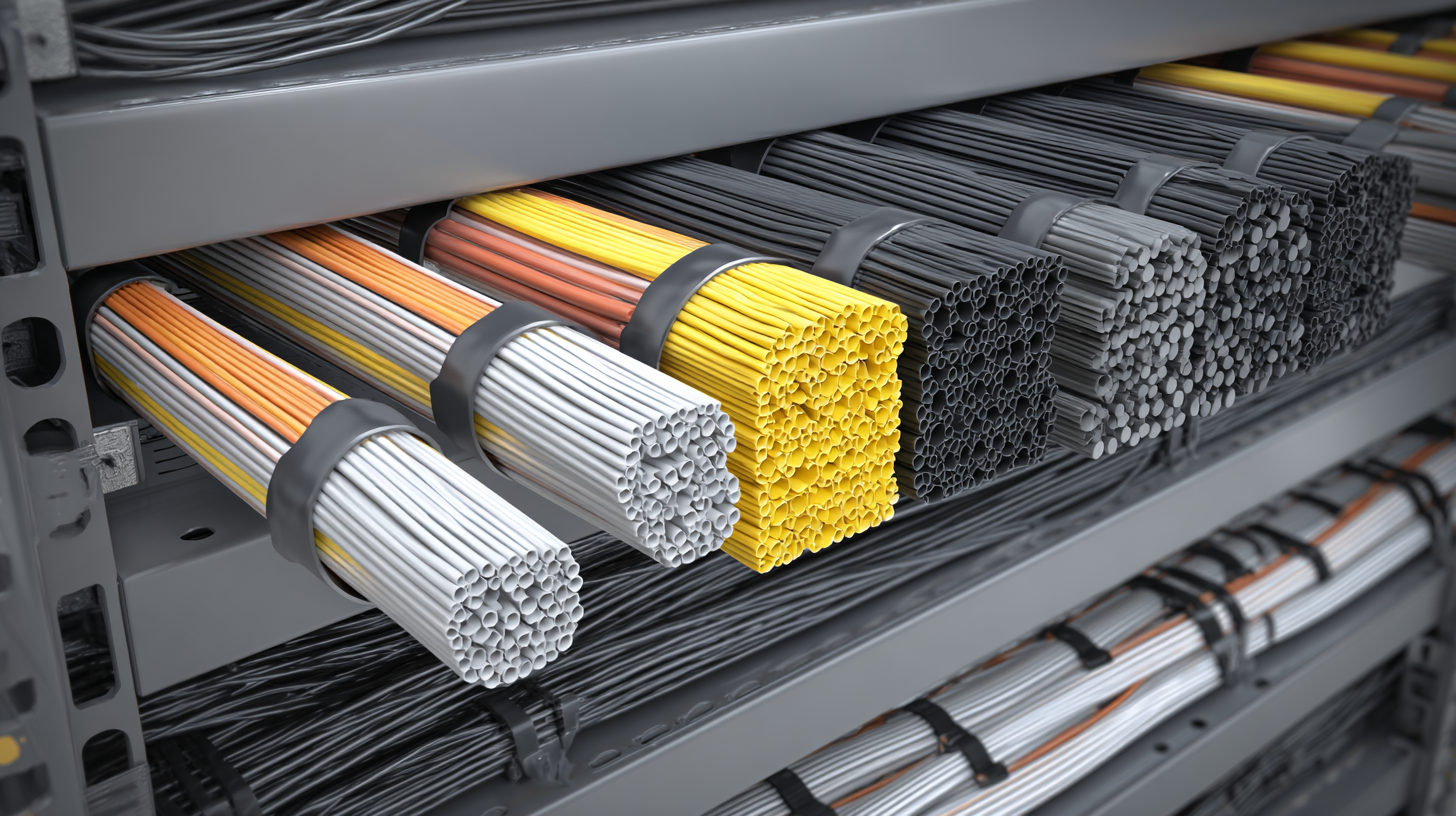

When it comes to ensuring a safe and efficient electrical installation, understanding the nuances of electric cable duct installation is crucial. Electric cable ducts play a vital role in protecting electrical cables from environmental factors, mechanical damage, and accidental tampering, ultimately prolonging their lifespan and enhancing system reliability. Implementing best practices during installation not only guarantees compliance with safety regulations, but also promotes optimal performance of electrical systems. In this article, we will delve into ten essential tips that will guide both novice and experienced installers in the effective installation of electric cable ducts. From selecting the appropriate materials to ensuring proper placement and securing methods, these insights will help you navigate the complexities of installing electric cable ducts safely and effectively, providing peace of mind for all electrical projects.

Understanding the Importance of Electric Cable Ducts in Safety and Efficiency

Electric cable ducts play a critical role in ensuring the safety and efficiency of electrical systems. As the U.S. electrical conduit market is projected to grow at a CAGR of 4.17%, reaching USD 1.72 billion by 2024, the importance of proper installation and use of these ducts cannot be overstated. They protect cables from environmental damage, facilitate maintenance, and ensure safe operation, particularly in high-voltage applications. The ongoing research into soil thermal behavior under ultra-high voltage operations highlights the need for reliable duct systems to enhance safety and sustainability in power delivery.

When installing electric cable ducts, it's essential to follow best practices to maximize safety and efficiency. First, ensure that you select the right size and type of duct for your specific installation needs. Utilizing a DC cable size calculator can streamline this process by providing accurate recommendations based on your system requirements. Second, keep ducts clear of excessive soil pressure through proper burial techniques, which can prevent damage and overheating. Lastly, regularly inspect and maintain duct systems to identify potential issues before they become critical. Adhering to these tips not only promotes operational safety but also extends the lifespan of electrical cables, aligning with the evolving standards set forth by modern building codes.

Electric Cable Ducts Installation Safety and Efficiency

Choosing the Right Materials for Durable and Safe Cable Duct Installation

When it comes to installing electric cable ducts, selecting the right materials is crucial for ensuring both durability and safety. High-quality materials not only withstand environmental stresses but also contribute to a safer installation. For instance, durable PVC or HDPE ducts are commonly used due to their resistance to impact and corrosion. They can protect electrical cables from moisture, chemicals, and physical damage, which is essential for maintaining the integrity of the electrical system over time.

Additionally, consider the installation environment when choosing materials. In areas prone to extreme temperatures or heavy traffic, it may be necessary to opt for reinforced or specifically rated cable ducts that offer enhanced protection. Furthermore, incorporating features like UV resistance can prevent degradation from sunlight exposure, prolonging the lifespan of the ducts. Investing time in selecting the right materials not only meets local safety regulations but also provides peace of mind, knowing that your cable installation is secure and reliable for years to come.

Step-by-Step Guide to Planning Your Electric Cable Duct Layout

When planning your electric cable duct layout, it is essential to approach the task with careful consideration and strategic thinking. The National Electrical Contractors Association (NECA) emphasizes the importance of a well-organized layout to minimize installation challenges and ensure safety. Begin by assessing the area where the ducts will be installed and create a blueprint that outlines the exact routing paths. This will help in visualizing where the ducts will run and in anticipating any potential obstructions.

When planning your electric cable duct layout, it is essential to approach the task with careful consideration and strategic thinking. The National Electrical Contractors Association (NECA) emphasizes the importance of a well-organized layout to minimize installation challenges and ensure safety. Begin by assessing the area where the ducts will be installed and create a blueprint that outlines the exact routing paths. This will help in visualizing where the ducts will run and in anticipating any potential obstructions.

Tip: Ensure you adhere to local building codes and regulations by consulting with a qualified electrician or a local authority at the initial planning phase. This will prevent costly modifications later on.

In addition, consider the load requirements of the cables you will be using. According to the International Electrotechnical Commission (IEC), oversizing ducts can lead to inefficiencies and increased installation costs. Evaluate the volume of cables and opt for ducts that allow for adequate airflow, which is vital for preventing overheating and ensuring cable longevity.

Tip: Utilize cable trays in conjunction with ducts to enhance organization and support, which can significantly reduce future maintenance costs and improve accessibility.

A thoughtful and systematic approach to your electric cable duct layout not only enhances the efficacy of the installation but also contributes to the overall safety and performance of the electrical system.

Common Mistakes to Avoid When Installing Electric Cable Ducts

When installing electric cable ducts, it's crucial to avoid common mistakes that could compromise safety and efficiency. According to a report by the National Fire Protection Association (NFPA), improper installation and routing of electrical cables contribute significantly to electrical fires, accounting for nearly 25% of all home fire incidents. One of the frequent errors made during installation is neglecting to consider the environmental conditions and local regulations. Failing to comply with these factors can lead to insulation degradation, increasing the risk of shorts and fires.

Another common mistake is underestimating the importance of proper cable separation. The Institute of Electrical and Electronics Engineers (IEEE) emphasizes that cables carrying different types of power or signals should maintain an appropriate distance from each other to prevent electromagnetic interference and thermal buildup. Additionally, installers often overlook the need for adequate ventilation within duct systems. A report from Underwriters Laboratories (UL) highlights that duct systems not designed for heat dissipation can overheat, leading to insulation failure. By steering clear of these pitfalls and adhering to industry standards, professionals can ensure a safer and more effective installation process.

10 Essential Tips for Installing Electric Cable Ducts Safely and Effectively

| Tip Number | Tip | Common Mistakes to Avoid |

|---|---|---|

| 1 | Plan the Layout | Ignoring spatial requirements |

| 2 | Select the Right Duct Size | Choosing ducts that are too small |

| 3 | Use Quality Materials | Using substandard or cheap materials |

| 4 | Maintain Proper Depth | Installing ducts too shallow |

| 5 | Ensure Adequate Support | Failing to secure ducts properly |

| 6 | Seal Ducts Properly | Neglecting to seal openings |

| 7 | Mark Duct Locations | Not marking positions clearly |

| 8 | Follow Safety Guidelines | Ignoring safety protocols |

| 9 | Consider Future Upgrades | Not planning for additional wires |

| 10 | Test After Installation | Skipping the testing phase |

Best Practices for Testing and Maintaining Installed Cable Ducts

Testing and maintaining installed cable ducts are critical components in ensuring both safety and efficiency in electrical systems. According to the International Electrotechnical Commission (IEC), regular inspection of cable ducts can prevent 80% of potential faults that could lead to equipment failure or safety hazards. Visual inspections should be conducted bi-annually, focusing on the integrity of duct materials, possible obstructions, and any signs of corrosion.

Additionally, employing advanced technologies like thermal imaging can proactively identify overheating issues, which are a common precursor to electrical failures.

Maintaining cable ducts also involves routine cleaning and ensuring that the ducts are free of dust, debris, and moisture. The National Fire Protection Association (NFPA) stresses the importance of this aspect, as clogged ducts can create hazardous conditions that may contribute to system overloads or potential fire risks.

Furthermore, conducting continuity and insulation resistance tests on the cables within the ducts can provide valuable insights into their operational performance, helping to detect issues before they escalate. Establishing a comprehensive maintenance schedule not only extends the lifespan of the cable ducts but also enhances the overall reliability of the electrical infrastructure.