10 Essential Tips for Choosing the Right Custom Cable for Your Needs?

In the world of electronics, choosing the right custom cable is crucial. According to a recent industry report by MarketsandMarkets, the custom cable market is projected to reach over $17 billion by 2025. This growth highlights the increasing demand for personalized solutions tailored to specific needs. Industry expert, Dr. Emily Zhang, emphasizes, “The right custom cable can significantly enhance performance and reliability for any application.”

Inappropriate cable choices can lead to inefficiencies or even equipment failures. Many users underestimate the importance of selecting the right specifications. A perfectly designed custom cable should match its intended environment and application flawlessly. However, this often requires careful consideration of various factors that many overlook.

Understanding the specific requirements for your custom cable is essential. While some may think that any cable will suffice, this is rarely true. Research shows that improperly matched cables can reduce performance by up to 30%. The nuances of cable design and material must be fully grasped to avoid costly mistakes. Making informed decisions can mean the difference between success and failure in your projects.

Understanding Your Specific Cable Requirements

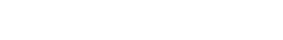

Choosing the right custom cable requires a keen understanding of your specific cable requirements. Identifying the transfer speed, resistance, and insulation needs is essential. According to a recent industry report, 70% of cable failures stem from mismatched specifications. This highlights the importance of knowing exactly what you need.

When selecting a cable, consider the environment where it will be used. Will it face extreme temperatures or moisture? Ensuring proper insulation can prevent costly failures. Be aware that not all cables are created equal in adverse conditions.

Tip: Analyze your data transfer needs. If you require a high-speed connection, opt for cables designed for that purpose. This can save you from future complications.

Another aspect to reflect on is the length of the cable. A common mistake is underestimating the impact of length on signal quality. Sometimes, longer cables lead to signal loss.

Tip: Always calculate the needed length accurately. A small error can lead to significant performance issues. Take time to verify your requirements. It’s better to be thorough than to rush and face problems later.

Identifying the Right Cable Specifications and Standards

When selecting custom cables, understanding specifications and standards is vital. The cable's material affects performance. For example, copper and aluminum have different conductivity. Choose based on your specific needs. Shielding is another key factor. It minimizes interference and improves signal quality. Consider the environment where the cable will be used.

Look into standards like UL or CSA. They indicate safety and reliability. Not all cables meet the same requirements. Check if the cable can handle the necessary voltage and temperature. Also, verify its flexibility for installation. It's easy to overlook details. Some cables may seem perfect but fall short in practical scenarios. Evaluate the intended purpose carefully to avoid costly mistakes.

Evaluating Cable Materials and Durability for Longevity

When choosing custom cables, material and durability are crucial. The right material can affect the cable's performance and lifespan. For instance, PVC is often used for its flexibility and low cost. According to industry reports, cables made of PVC can last around 5 to 10 years under normal conditions. However, these cables may not withstand extreme temperatures or exposure to chemicals.

In contrast, polyurethane cables offer better durability and longevity. They can endure harsher environments, making them ideal for industrial applications. A study by the International Cable Manufacturers Federation indicates that polyurethane cables can last up to 20 years if properly maintained. This longevity can lead to significant cost savings over time, reducing frequent replacements.

Choosing between these materials requires careful consideration. If the environment is demanding, polyurethane may be the better choice. However, for less rigorous applications, PVC could be sufficient. Remember, the cable's performance depends not just on the material but also on how it's used. Poor installation can reduce any cable's lifespan. Reflect on your specific needs and evaluate the potential trade-offs between cost and durability.

Durability Comparison of Custom Cable Materials

Choosing the Appropriate Length and Flexibility

When selecting a custom cable, flexibility and length are crucial. Too stiff may limit movement. Conversely, excessive length can lead to signal loss. A study from the International Electrotechnical Commission notes that proper cable length significantly impacts transmission quality. It's vital to analyze your specific use case.

Consider the working environment. If the cable will be bent frequently, opt for a flexible design. Look for materials that maintain performance even under stress. In contrast, a rigid cable might work better for stationary applications. Think about where it will be placed. Uneven surfaces may require more flexibility to avoid damage.

Tip: Measure the distance accurately. Adding a cushion of a few inches can help but avoid excessive slack. Too much excess can create clutter and signal degradation.

Tip: Test multiple configurations before making a final choice. A cable that fits today may not suit future needs. Underestimating this can lead to purchasing new cables sooner than expected. Flexibility and length play a significant role in the longevity of your custom cable solution.

Budgeting for Custom Cables: Costs and Value Considerations

When budgeting for custom cables, costs can vary significantly based on materials and specifications. According to industry reports, custom cable prices can range from $1 to $10 per foot. Lower costs often compromise quality. High-end materials, like Teflon and copper, drive prices higher, but their durability may justify the expense.

Value considerations must also factor in long-term performance and reliability. Statistically, investing in quality cables can reduce maintenance costs by up to 30%. A poorly chosen cable can lead to frequent replacements and unexpected downtime. In sectors like telecommunications, this could result in revenue losses.

Many customers focus solely on upfront costs. This short-sighted approach can backfire. Infrastructure failures often stem from inadequate cables. In a study by an industry consultant, 45% of businesses reported issues due to subpar cabling. Reflecting on these factors reveals the need for a balanced view on price versus quality in custom cable selection.

Related Posts

-

10 Essential Tips to Choose the Best Cable Supplier for Your Business Needs

-

10 Essential Tips for Choosing the Right Cable Supplier for Your Business Needs

-

How to Choose the Right Custom Cable for Your Needs?

-

Top Home Electrical Tips for Safe and Efficient Living?

-

2025 Top 5 Cable Conduits: The Best Solutions for Your Wiring Needs

-

10 Essential Tips for Managing Duct Cable Effectively