Understanding the Basics of Cable and Wire Types for Everyday Applications

In the rapidly evolving landscape of technology, understanding the various types of cable and wire is crucial for both professionals and everyday users. According to a recent report by MarketsandMarkets, the global wire and cable market is projected to reach over $300 billion by 2025, driven by the increasing demand from sectors such as telecommunications, energy, and construction. With advancements in materials and manufacturing techniques, the differentiation between cable and wire types has become more pronounced, influencing their respective applications. From electrical installations in residential buildings to complex data transmission systems, the choice of cable and wire directly impacts performance, safety, and efficiency. This foundational knowledge is vital for making informed decisions in various scenarios, ultimately leading to enhanced functionality and reliability in our daily tasks.

Types of Electrical Cables: A Comprehensive Overview

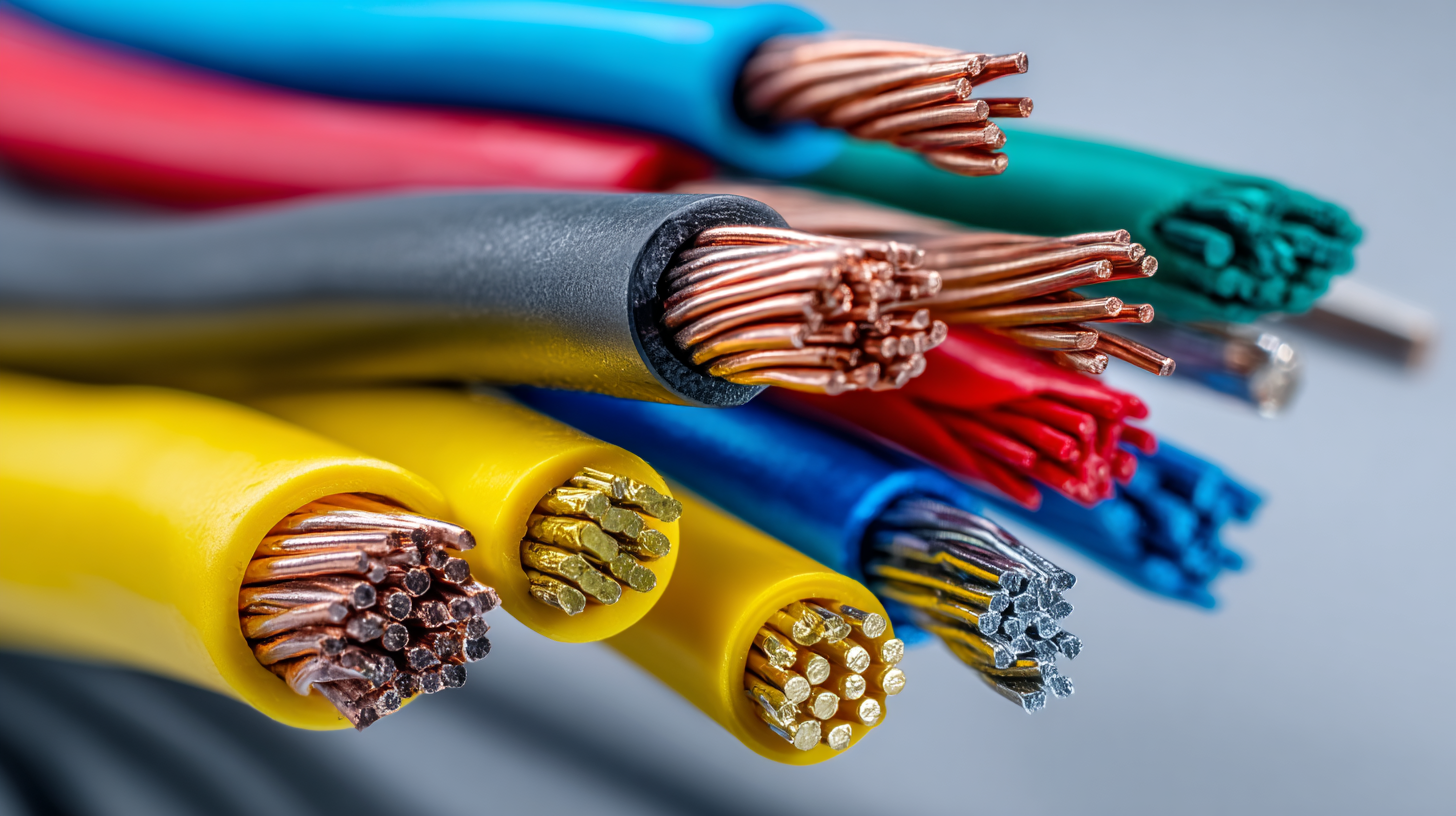

When diving into the world of electrical cables, it's essential to comprehend the different types available and their specific applications. The most common categories include non-metallic sheathed cables (NM), armored cables (AC), and flexible cords. NM cables, often used in residential wiring, offer excellent insulation and protection against moisture, making them suitable for indoor applications. In contrast, armored cables, which feature a protective metal layer, are designed for environments where physical damage is a concern.

Tips: When selecting a cable, consider the environment in which it will be used. Ensure the cable's insulation rating matches the conditions—wet, dry, or damp—to maintain safety and performance.

Additionally, flexible cords are perfect for temporary setups and portable applications due to their increased flexibility and durability. These cords are commonly found in tools and appliances, where movement is necessary.

Tips: For any connection or installation, always check the ampacity ratings to ensure the cable can handle the electrical load, preventing overheating and potential hazards.

Understanding the Basics of Cable and Wire Types for Everyday Applications

Understanding Wire Gauge and Its Importance in Applications

When selecting the right wire for your electrical projects, understanding wire gauge is crucial. Wire gauge, measured in American Wire Gauge (AWG), indicates the wire's diameter and influences its current-carrying capacity. A smaller gauge number corresponds to a thicker wire, which can handle more electricity without overheating. This is particularly important in applications requiring high power, such as household appliances or industrial machinery.

**Tip:** When replacing or installing electrical wiring, always choose the appropriate gauge to prevent hazards like electrical fires or equipment malfunction. For instance, a 12 AWG wire is suitable for general-purpose wiring in most homes, while 14 AWG might suffice for lighter loads.

Additionally, recognizing the effect of wire length on gauge selection is essential. Longer runs of wire can lead to voltage drop, so using a thicker gauge is advisable for greater distances.

**Tip:** If running wire over long distances, consider going one or two gauges lower (thicker wire) to combat voltage drop and ensure efficient operation of your devices. Always consult local electrical codes to stay compliant and safe while working on your projects.

Insulation Materials: Choosing the Right Type for Your Project

When selecting insulation materials for your project, it's crucial to consider several key qualities that ensure you make the right choice.

First, the thermal resistance, or R-value, measures how effectively an insulation material can resist heat flow. A higher R-value indicates better insulating properties, which is particularly important in climates with extreme temperatures.

Additionally, consider the moisture resistance of the insulation; materials that can withstand humidity will help prevent mold growth and maintain the integrity of your structure. It's also essential to evaluate the environmental impact, opting for materials that are sustainable and have a lower carbon footprint.

Furthermore, the type of insulation installation should be a priority.

Choosing a qualified installer with experience in the specific insulation material is vital for achieving optimal results. Look for professionals who can assess your space and recommend the best insulation type based on your needs.

In Canberra, resources are available to connect you with skilled installers who can provide you with the expertise required for your insulation project. Always seek out reviews and recommendations to ensure you make an informed decision for your home's insulation needs.

Common Applications of Various Cable Types in Everyday Life

When it comes to everyday applications, understanding the various types of cables and wires is essential. For instance, power cables are crucial for delivering electricity to homes and businesses. These cables are commonly used in residential settings for lighting and appliance power supply. They come in various gauges, with heavier gauges capable of carrying more electrical current, making them suitable for high-demand appliances such as refrigerators and air conditioners.

Similarly, communication cables, such as coaxial and Ethernet cables, play a vital role in connecting devices for internet and television services. Coaxial cables are often used for cable television, providing a reliable connection for clear audio and video transmission. On the other hand, Ethernet cables are standard in networking, allowing for high-speed internet access in homes and offices. Understanding these cables helps individuals not only in making informed purchasing decisions but also in troubleshooting connectivity or power issues when they arise.

Safety Considerations When Selecting Electrical Wires and Cables

When selecting electrical wires and cables, safety should always be the top priority. According to the National Fire Protection Association (NFPA), faulty wiring is a leading cause of electrical fires, accounting for approximately 67,000 home fires annually. This statistic underscores the importance of choosing appropriate wire types that can withstand the demands of their intended applications. For instance, using a wire rated for higher voltage applications in low-voltage situations can lead to overheating, posing a significant fire risk.

**Tips**: Always check the gauge size of wires; using too small a gauge can lead to overheating. The American Wire Gauge (AWG) system provides a reliable way to assess wire suitability for specific tasks.

Moreover, the insulation type and temperature rating of cables are crucial to ensure safety. Cables come with different insulation materials such as PVC, rubber, and thermoplastic elastomer (TPE), each suitable for specific environments. For instance, outdoor cables must be resistant to UV radiation and moisture to prevent deterioration. According to industry reports, approximately 30% of electrical failures can be traced back to improper wire insulation in hazardous environments.

**Tips**: Use UL-listed wires and cables to ensure compliance with safety standards. Checking for the Underwriters Laboratories (UL) mark can provide assurance of the product's safety and performance under specified conditions.

Understanding the Basics of Cable and Wire Types for Everyday Applications - Safety Considerations When Selecting Electrical Wires and Cables

| Wire/Cable Type | Applications | Ampacity Rating (Typical) | Safety Considerations |

|---|---|---|---|

| THHN/THWN | General purpose wiring, industrial applications | 90°C - 15 A for 14 AWG, up to 85 A for 6 AWG | Use appropriate gauge for load, ensure proper insulation |

| NM Cable (Romex) | Residential wiring, indoor applications | 60°C - 15 A for 14 AWG, 20 A for 12 AWG | Keep away from moisture, use in dry locations |

| UF Cable | Underground installations, outdoor lighting | 60°C - 20 A for 12 AWG | Burial depth requirements, moisture resistance |

| MTW | Machine tool wiring, appliance connections | 90°C - 20 A for 12 AWG | Flexible use, check for abrasion resistance |

| SJO Cable | Heavy-duty extension cords, portable appliances | 60°C - 15 A for 14 AWG | Evaluate voltage drops, ensure proper use for equipment |

Related Posts

-

10 Essential Tips for Installing Electric Cable Ducts Safely and Effectively

-

Understanding the Importance of Duct Cable in Modern Communication Systems

-

The Ultimate Guide to Effective Cable Management Strategies for a Tidy Workspace

-

Maximizing Efficiency: How Electric Cable Ducts Improve Cable Management and Reduce Risks in Modern Infrastructure

-

Revolutionize Your Workspace: Unleashing the Power of Innovative Cable Holders

-

Ultimate Guide to Innovative Cable Holder Solutions for a Clutter Free Space